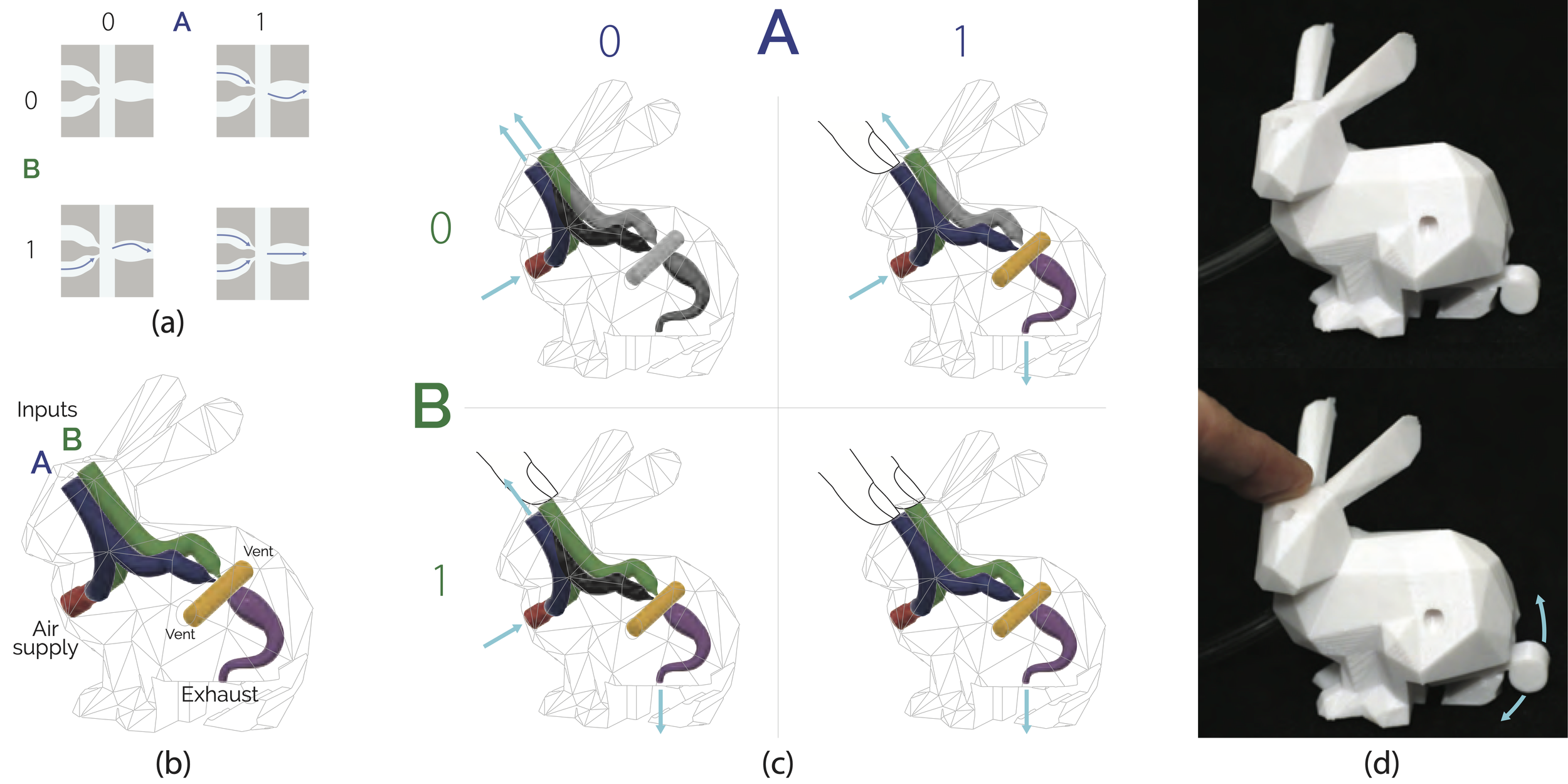

Throughout this portfolio I’ve presented a bunch of projects that help create interactive devices using 3D printers, that’s kind of my thing. All these projects have one thing in common: they need an external computation device in order to fully work. Be it to help identify where you touched, or blowed on, the object, or control how the object moves, unless there is a computer calling the shots these objects aren’t very useful. This got me thinking, how can we print a whole computer inside the object using a 3D-printer? AirLogic is my response to this question. AirLogic is a technique to create fully self-contained, electronics-free devices that can sense input, process logic, and provide output using air. In a nutshell, AirLogic works by interpreting the presence of an air jet as a binary 1, and its absence a 0. We developed a series of components that take this metaphor and apply it to input, logic and output tasks, and connect them together to create our electronics-free devices.

AirLogic has a lot of interesting details that differentiate it from other techniques. For example, the devices created with AirLogic require very minimal assembly, often just inserting one of the moving parts of the device that had to be printed separately. Also, AirLogic devices are stateless. Because AirLogic devices are powered by air jets being routed through the interior of the device, once used there is no need to reset the device to its original position. Finally, there is no need for special printers, assemblies, or electronics. AirLogic devices can be created using off-the-shelf printers and plastics, and can be powered even using your lungs (!).

AirLogic enables a variety of input and output types

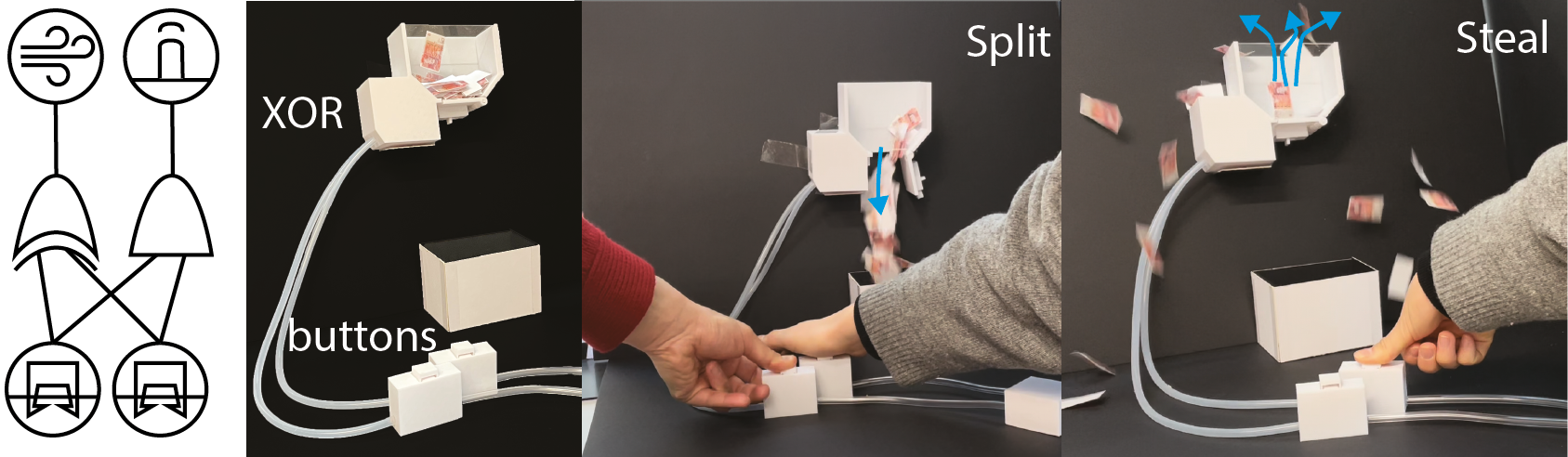

A cool thing about AirLogic is that you can use its components to design and create the device that fits your specific needs. In total, AirLogic can enable five different types of input types, and four different types of output types.

For example, using AirLogic’s components, we created a Steal/Split game where only when both “thieves” choose to steal, they split the earnings.

Another cool demonstration of AirLogic’s expressivity is our example of a whistle. Using our slider and pitch components, you can create a lung-powered flute to play your favorite songs.

AirLogic can help prototyping interactive devices

But wait, you may be thinking, 3D printing takes loads of time. What if I want to very quickly prototype and test a device? AirLogic has got you covered, too. AirLogic components can be either embedded to the inside of models, or printed on their own as air-powered Lego pieces. This way you can very quickly prototype what your device should do with them, connecting them using plastic tubes, and once you’re satisfied with it’s workings start modeling its final shape.

An example of how AirLogic components can be printed individually to test a device.

But what if you’re not sure on the final shape of the device yet, but you’re set on how it should work? Well, we found that we could print the “brains” of the device (meaning all its internal components) and just mold the outside as we wish using state-of-the-art prototyping materials (aka Play-Doh).

An example of a Play-Doh dog using the bunny’s (above) logic

You can download this paper from the ACM Digital Library, or directly from this website.